Planetary Gearbox

Discover Planetary Gearboxes Engineered for Precision, Efficiency & Reliability

The preferred choice for high-torque, compact, and high-precision motion control in robotics, automation, automotive, renewable energy, and aerospace.

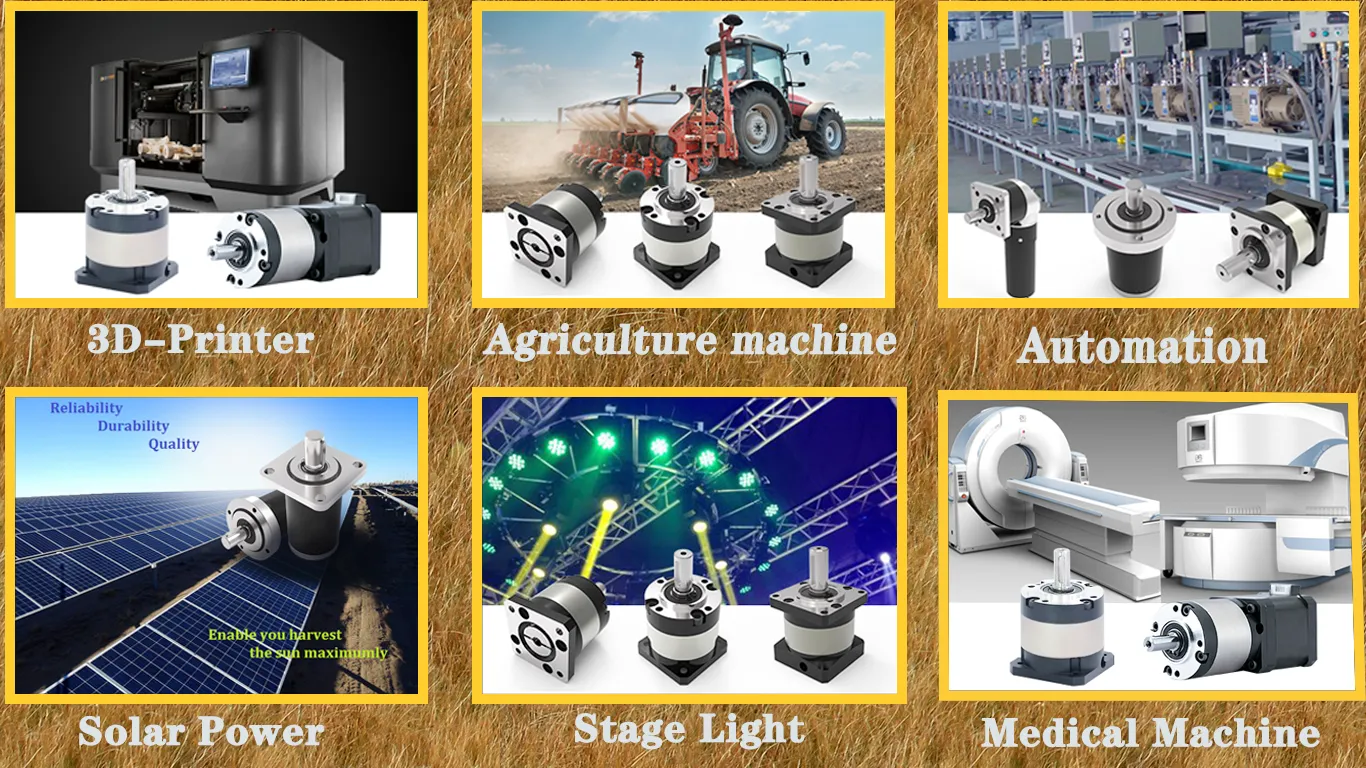

Applications

Widely Used Across Industries

Industrial Robots & Automation、CNC Machines & Machine Tools、Electric Vehicles & Automotive Transmissions、Wind Turbines & Solar Trackers、Medical Equipment & Surgical Robots、Aerospace & Defense Systems、Packaging & Printing Machinery…

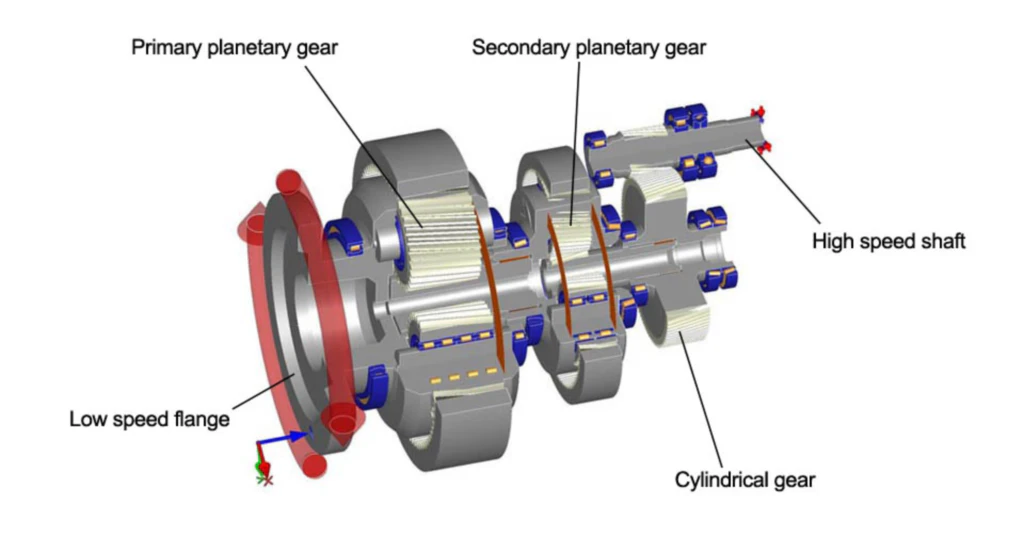

What is a Planetary Gearbox?

A planetary gearbox (also called planetary reducer) is a high-performance gear system consisting of a sun gear, multiple planet gears, a ring gear, and a planet carrier. Its unique design allows power to be distributed across multiple planet gears, delivering significantly higher torque in a very compact space compared to traditional gear systems.

How Does a Planetary Gearbox Work?

Power is transmitted from the sun gear to the planet gears. As the planets rotate on their own axes and revolve around the sun gear while meshing with the ring gear, they produce a high reduction ratio and multiplied output torque. The planet carrier transfers the output motion.

Why Choose Planetary Gearboxes?

- High torque density in compact size

- Efficiency up to 98%

- Low backlash (as low as 1 arcmin)

- Excellent load distribution

- High precision and rigidity

- Multiple reduction stages available

- Long service life and reliability

Planetary Gearbox for Sale

The following are some of our featured products. Our factory offers the most comprehensive range of gearboxes. If you have any needs, please feel free to contact us for a free product catalog.

Common Parameters of Planetary Gearboxes

| Parameter | Typical Range / Value | Description |

|---|---|---|

| Gear Ratio | 3:1 to 3000:1+ | Ratio of input to output speed; single-stage typically 3:1–10:1, multi-stage expandable |

| Nominal Output Torque | 100 Nm to 10,000+ Nm | Continuous torque capacity; depends on motor matching and gear ratio |

| Acceleration Torque | 1.5–2 × Nominal Torque | Short-term peak load capability (limited to <1000 cycles/hour) |

| Full Load Efficiency | 90% to 98% | Energy transmission efficiency; higher with helical gear designs |

| Backlash | 1–15 arcmin (Precision type ≤ 3 arcmin) |

Output shaft free play; precision models offer ultra-low backlash |

| Rated Input Speed | 1,000 to 6,000 RPM | Maximum continuous input speed; derating required above 20°C ambient |

| Power Rating | 0.09 kW to 150+ kW | System power capacity suitable for various application scales |

| Noise Level | 50–75 dB | Operational noise; low-noise versions use precision gearing |

| Average Lifespan | 5,000 to 20,000+ hours | Based on load and maintenance; bearings and lubrication are critical |

| Size / Weight | Diameter 50–500 mm Weight 1–100+ kg |

Depends on power and number of stages; compactness is a key advantage |

Data based on 2025–2026 industry standards • Actual values may vary by manufacturer and model