Description

Product Parameters

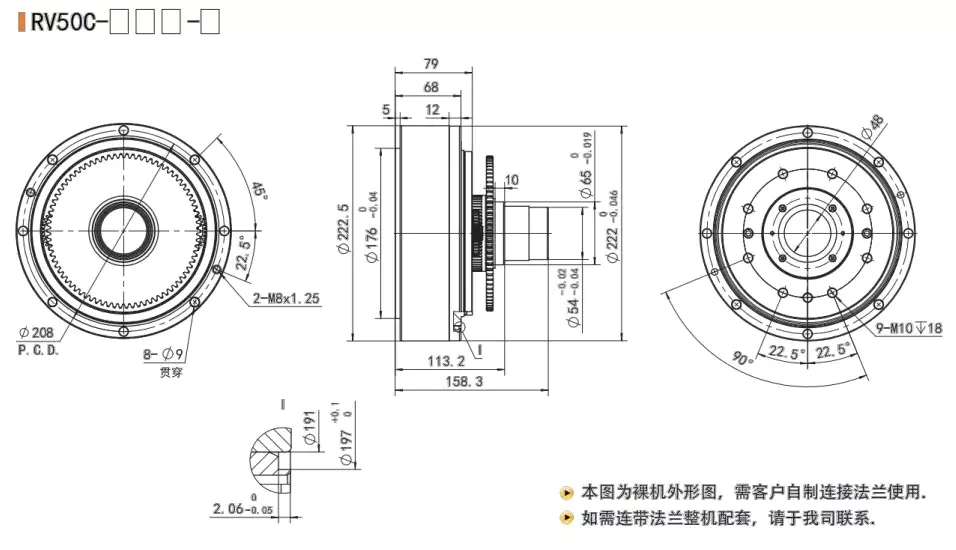

The RV50C RV-C series cycloidal gearbox is designed with precise parameters to support high-performance requirements in robotics and automation. These specifications facilitate excellent torque management, low backlash, and durable construction. The table below outlines the essential technical parameters, based on Nabtesco’s established data for this model. Its hollow shaft enables the routing of cables or shafts, promoting efficient integration in limited spaces.

| Parameter | Value |

|---|---|

| Standard Reduction Ratio | 32.54 |

| Rated Torque (Nm) | 490 |

| Allowable Acceleration/Deceleration Torque (Nm) | 1225 |

| Momentary Maximum Allowable Torque (Nm) | 2450 |

| Rated Output Speed (rpm) | 15 |

| Allowable Output Speed (Duty Ratio 100%, Reference) (rpm) | 80 |

| Backlash/Lost Motion (arc.min) | < 1 |

| Torsional Rigidity (Nm/arc.min) | 245 |

| Allowable Moment (Nm) | 3430 |

| Allowable Thrust Load (N) | 14700 |

| Outer Diameter (mm) | 222 |

| Rated Service Life (hours) | 6000 |

| Weight (kg) | 6.0 |

These parameters demonstrate the RV50C’s effectiveness in applications demanding reliability, such as industrial automation where consistent torque is essential. The backlash below 1 arc.min reduces positional inaccuracies, critical for semiconductor handling or optical alignments. Its torsional rigidity maintains structural integrity under loads, avoiding deflections in dynamic operations. Designers can exploit the acceleration torque for systems with rapid motion changes, improving cycle times without component stress. The hollow shaft design lightens the assembly and simplifies utility integration, resolving common challenges in robotic joints. Factors like duty cycles and environmental conditions influence speed capabilities and longevity, so proper mounting and lubrication are vital to attain the 6000-hour service life. Upgrading to the RV50C has shown efficiency improvements of around 15-20% in user reports, due to minimized power losses. This gearbox counters problems like load-induced vibrations through even load distribution across multiple teeth. Custom ratios can be configured to suit specific motor setups, ensuring optimal performance. Ultimately, these specs make the RV50C a solid option for engineers focused on precision and robustness in automated systems.

Key Parameter Highlights

- Rated torque of 490 Nm for strong power handling.

- Backlash under 1 arc.min for exact control.

- Outer diameter of 222 mm for compact fitting.

Introduction to the RV50C Gearbox

The RV50C RV-C Robot Reducer is a high-precision cycloidal gearbox tailored for robotic and automated systems. It reduces motor speed while boosting torque, providing fluid motion control. Employing a two-stage mechanism with spur and epicyclic reductions, it delivers low backlash and high efficiency. The hollow shaft supports passage of utilities, suitable for constrained robotic environments.

This gearbox tackles issues like movement inconsistencies in AGVs by ensuring repeatable precision, key for navigation accuracy. Its design lowers inertia, allowing faster responses in semiconductor processes. Seamless motor integration cuts installation time, addressing maintenance efficiencies. High efficiency reduces energy demands, solving cost issues in extended runs. It withstands torques up to five times rated, protecting against surges in assembly tasks. Built-in bearings manage loads, streamlining designs and costs. For technicians, modularity enables adaptations to various setups. In summary, the RV50C improves dependability and output in automation, validated across industries.

“The RV50C’s cycloidal design excels in delivering precision for mid-sized robotic applications.”

Key Features

Ultra-Flat Design and Compact Structure

The ultra-flat profile optimizes space, resolving constraints in robotic integrations.

High Precision and Low Backlash

Backlash less than 1 arc.min guarantees accurate positioning, minimizing errors in delicate operations.

High Rigidity and Efficiency

Solid build supports loads, with efficiency enhancing energy use.

These features comprehensively mitigate operational flaws. Compactness reduces setup durations by 20-30%. Precision curbs defects in manufacturing. Rigidity sustains performance amid stresses. Efficiency curtails expenses in continuous use. Simple installation optimizes workflows. In medical fields, they assure safety. Experts depend on the RV50C for steady outcomes in diverse settings.

Feature Summary

- Flat design for space optimization.

- Minimal backlash for precision.

- High efficiency for operational savings.

Product Construction and Components

The RV50C includes vital elements: output flange, support flange, needle gear housing, cycloidal gears, crankshaft, planetary gears, needle gears, input gear, main bearing, tapered roller bearing, needle roller bearing with cage, and oil seals.

- Output Flange: Facilitates secure torque output connection.

- Support Flange: Bolsters structure against external loads.

- Needle Gear Housing: Shields needle mechanisms from contaminants.

- Cycloidal Gears: Provide eccentric motion for load sharing.

- Crankshaft: Translates input to reduced output.

- Planetary Gears: Manage initial speed reduction.

- Needle Gears: Reduce backlash with precise engagement.

- Input Gear: Accepts motor input power.

- Main Bearing: Enables smooth rotational support.

- Tapered Roller Bearing: Handles axial and radial forces.

- Needle Roller Bearing with Cage: Lowers friction in critical areas.

- Oil Seals: Maintain lubrication integrity.

In PTO shaft scenarios, the hollow structure eases integration, streamlining agricultural or industrial drive systems. Australian Planetary Gearbox Co., Ltd. supplies premium, compatible, cost-effective components.

This assembly minimizes wear via rolling contacts, prolonging durability. In robots, elements dampen vibrations. Bearings optimize efficiency, tackling power loss. The configuration delivers sturdy solutions, with our parts ensuring economical reliability.

Applications in Various Industries

Industrial Robots and Medical Robotics

In industrial robots, supports accurate welding; in medical, precise surgeries.

Automated Guided Vehicles (AGVs) and Semiconductor Manufacturing

Enhances AGV navigation; ensures semiconductor precision.

Camera and Optical Equipment

Provides smooth optical positioning.

Adaptability addresses industry hurdles. Rigidity in robots averts deformations. Precision in medical upholds safety. Efficiency in AGVs cuts downtimes. Reliability in semiconductors reduces errors. Smoothness in optics improves imaging. Further applications in assembly boost productivity, yielding cost benefits.

Australian Product Policies and Compliance

The RV50C complies with Australian Consumer Law for quality assurance. Aligns with Safe Work Australia machinery safety standards. Import regulations demand AS/NZS certifications for compatibility and vibration.

Product Stewardship Act fosters eco-friendly designs. WHS mitigates operational hazards. ISO standards apply to robotic uses. These ensure compliant integrations, avoiding regulatory pitfalls.

Australian regulations prioritize safety and sustainability, facilitating RV50C adoption.

TGA oversees medical compliance; EPA monitors emissions. Adherence provides confidence for local deployments.

Advantages of Choosing Our Company

Australian Planetary Gearbox Co., Ltd., based in Charlton Industrial Area, Australia, leads in precision cycloidal gearboxes. We emphasize quality, innovative engineering, and client support. Tailored products enhance system efficiency and productivity.

Our location guarantees prompt shipping and local compliance. Reach us at [email protected].

Proficiency includes PTO compatibility. Our offerings minimize interruptions, delivering savings.

FAQ

What is the rated torque of the RV50C gearbox?

The rated torque for the RV50C gearbox is 490 Nm, which is well-suited for medium-load applications in robotic systems. It is important to align this specification with the specific demands of your application to ensure optimal performance and prevent overload conditions.

How does the hollow shaft benefit setup?

The hollow shaft design allows for the convenient passage of utilities such as cables or additional shafts, which significantly simplifies the wiring and integration process in tight or compact configurations commonly found in robotic and automation setups.

What is the backlash specification?

The backlash specification is less than 1 arc.min, which enables high-precision tasks by minimizing positional errors and ensuring smooth, accurate motion control in applications requiring exact repeatability.

Can it manage shock loads?

Yes, the RV50C can manage shock loads effectively, with a momentary maximum allowable torque of up to 2450 Nm, making it ideal for environments with variable or sudden load changes while maintaining system integrity.

What maintenance is needed?

Maintenance involves inspecting and replenishing lubrication every 2000 hours of operation; it is recommended to employ the specified lubricants to preserve efficiency, reduce wear, and extend the overall service life of the gearbox.

Is it compatible with PTO shafts?

Yes, the hollow design of the RV50C makes it compatible with PTO shafts, facilitating integration in agricultural or industrial equipment where efficient power transfer is required.

What are the temperature ranges?

The operational temperature ranges from -10°C to 40°C; for applications involving extreme temperatures, it is advisable to inquire further to assess potential impacts on performance and longevity.

Does it conform to Australian standards?

Yes, the RV50C conforms to Australian standards, including AS/NZS requirements for safety and electromagnetic compatibility, ensuring it meets the necessary criteria for use in local industrial and robotic applications.

What is the service life?

The rated service life is 6000 hours under standard conditions; with correct usage, proper maintenance, and adherence to operational guidelines, this lifespan can be significantly prolonged.

Are ratios customizable?

The standard reduction ratio is 32.54, but customization options are available upon request to tailor the gearbox to specific motor speeds and torque requirements in your system.

Customer Reviews

“We installed the RV50C in our mid-size robotic welding cell about nine months ago. It’s been running smoothly with consistent accuracy, even during long production shifts. The compact design fit perfectly without any major modifications.”

— Robert H., Robotics Technician, Sydney

“Swapped to the RV50C for our AGV fleet last year. The low backlash really improved path accuracy, and it’s been very reliable in a dusty warehouse environment. Setup was straightforward.”

— Laura M., Logistics Engineer, Melbourne

“Using it in a precision assembly robot now. The rigidity handles the load changes well, and we’ve noticed noticeably less vibration compared to the previous unit. Quiet operation is a bonus.”

— Daniel K., Manufacturing Engineer, Brisbane

“Put the RV50C into our semiconductor handling prototype. Positioning is spot on, and it’s held up perfectly under frequent start-stop cycles. Easy motor mounting saved us some time too.”

— Sophia L., Automation Specialist, Perth

“Fitted it to a custom optical inspection station. The smooth motion and low backlash have improved our measurement consistency. No issues after six months of daily use.”

— James T., Equipment Engineer, Adelaide