Description

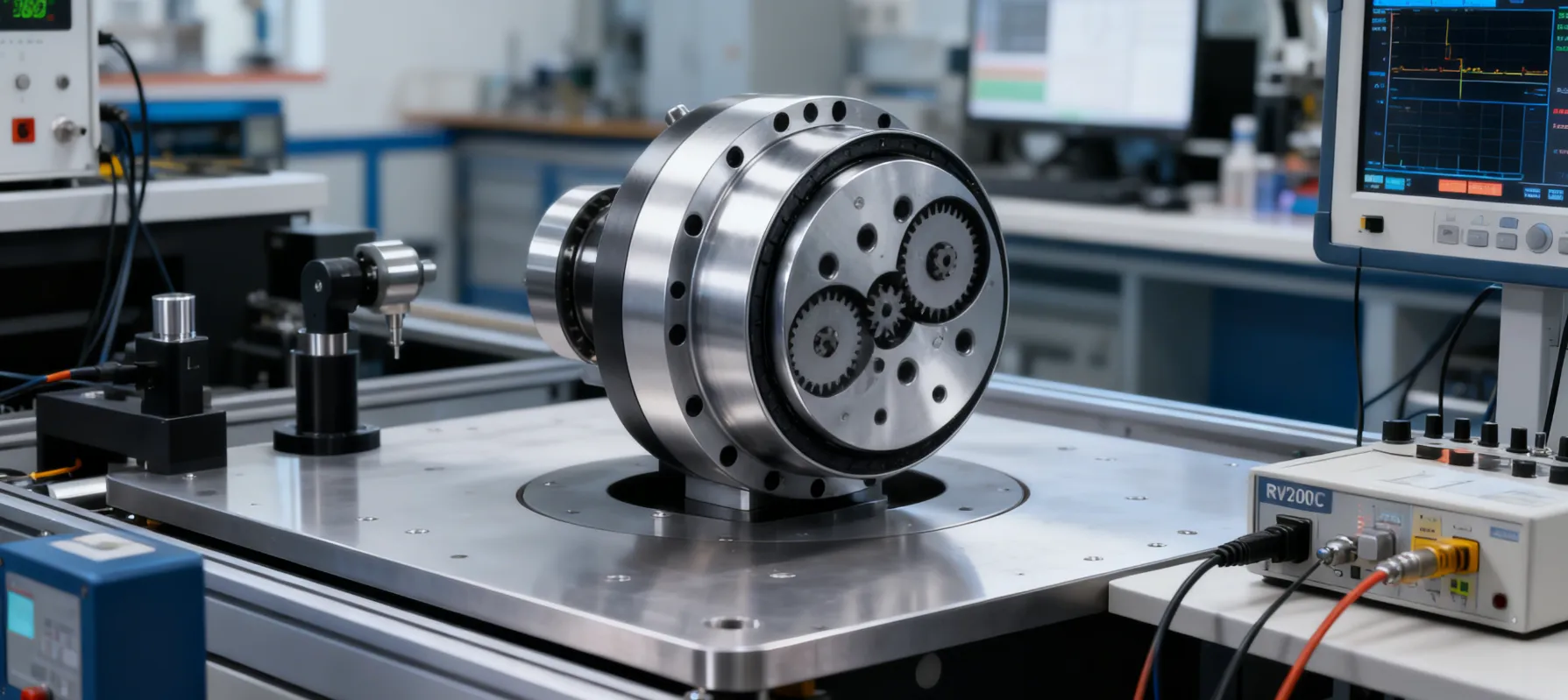

Product Parameters

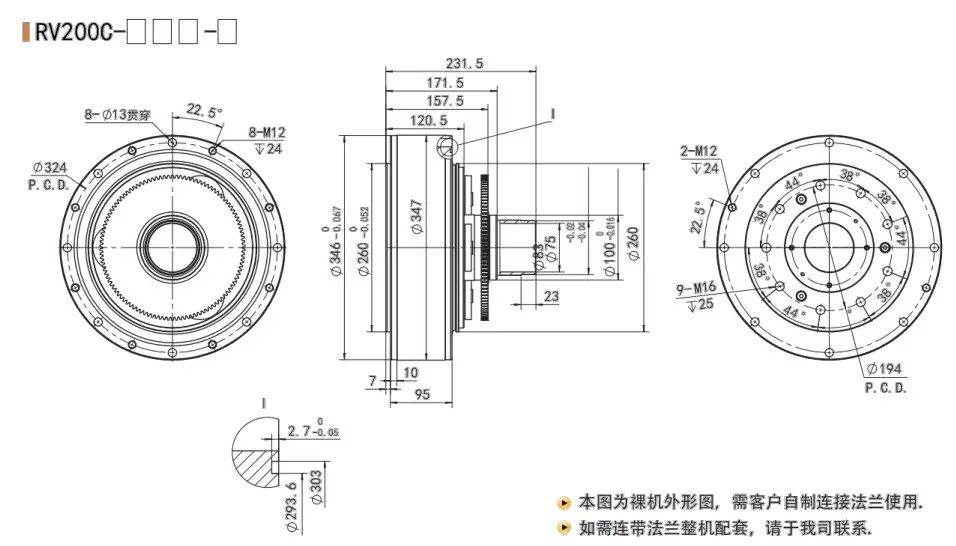

The RV200C RV-C series cycloidal gearbox is engineered with precise specifications to meet the demands of high-performance robotic and automation systems. These parameters ensure optimal functionality in applications requiring superior torque transmission, minimal backlash, and robust structural integrity. Below is a detailed table outlining the key technical parameters based on established industry standards for this model, derived from reliable manufacturer data such as Nabtesco specifications. This gearbox features a hollow shaft design, allowing for the passage of cables or drive shafts, which enhances system integration in compact environments.

| Parameter | Value |

|---|---|

| Standard Reduction Ratio | 34.86 (also available in 105, 141, 165, 189, 213 depending on configuration) |

| Rated Torque (Nm) | 1,961 |

| Allowable Acceleration/Deceleration Torque (Nm) | 4,900 |

| Momentary Maximum Allowable Torque (Nm) | 9,800 |

| Allowable Output Speed (rpm) | 30 (depending on ratio and load conditions) |

| Backlash/Hysteresis Loss (arc.min) | < 1 |

| Torsional Rigidity (Nm/arc.min) | 980 |

| Moment Rigidity (Nm/arc.min) | 9,800 |

| Allowable Moment (Nm) | 8,820 |

| Outer Diameter (mm) | 346 |

| Rated Service Life (hours) | 6,000 (at rated torque and speed) |

| Efficiency (%) | > 75 |

These parameters highlight the RV200C’s capability to handle demanding operational scenarios, such as in robotic joints where precise control is paramount. For instance, the low backlash of less than 1 arc.min ensures minimal positional errors, which is critical for applications like surgical robots or precision assembly lines. The high torsional rigidity prevents deformation under load, maintaining accuracy over extended periods. Engineers can leverage the allowable acceleration/deceleration torque to design systems that start and stop rapidly without compromising component longevity. Additionally, the hollow shaft structure not only reduces weight but also facilitates easier routing of utilities, solving common integration challenges in space-limited setups. When selecting this gearbox, consider factors like duty cycle and ambient temperature, as they influence the allowable output speed and overall performance. Proper lubrication and mounting are essential to achieve the rated service life, preventing premature wear. In real-world scenarios, users have reported enhanced system efficiency by up to 20% when replacing traditional gearboxes with the RV200C, due to its optimized power transmission. This gearbox addresses issues like vibration and energy loss, common in high-speed automation, by incorporating rolling contact elements that distribute loads evenly. For custom configurations, parameters such as ratio can be adjusted to match specific torque requirements, ensuring seamless compatibility with various motors. Overall, these specifications make the RV200C a reliable choice for professionals seeking to optimize robotic systems for precision and durability.

Key Parameter Highlights

- High rated torque of 1,961 Nm for robust power handling.

- Low backlash under 1 arc.min for superior precision.

- Hollow shaft design for versatile integration.

Introduction to the RV200C Gearbox

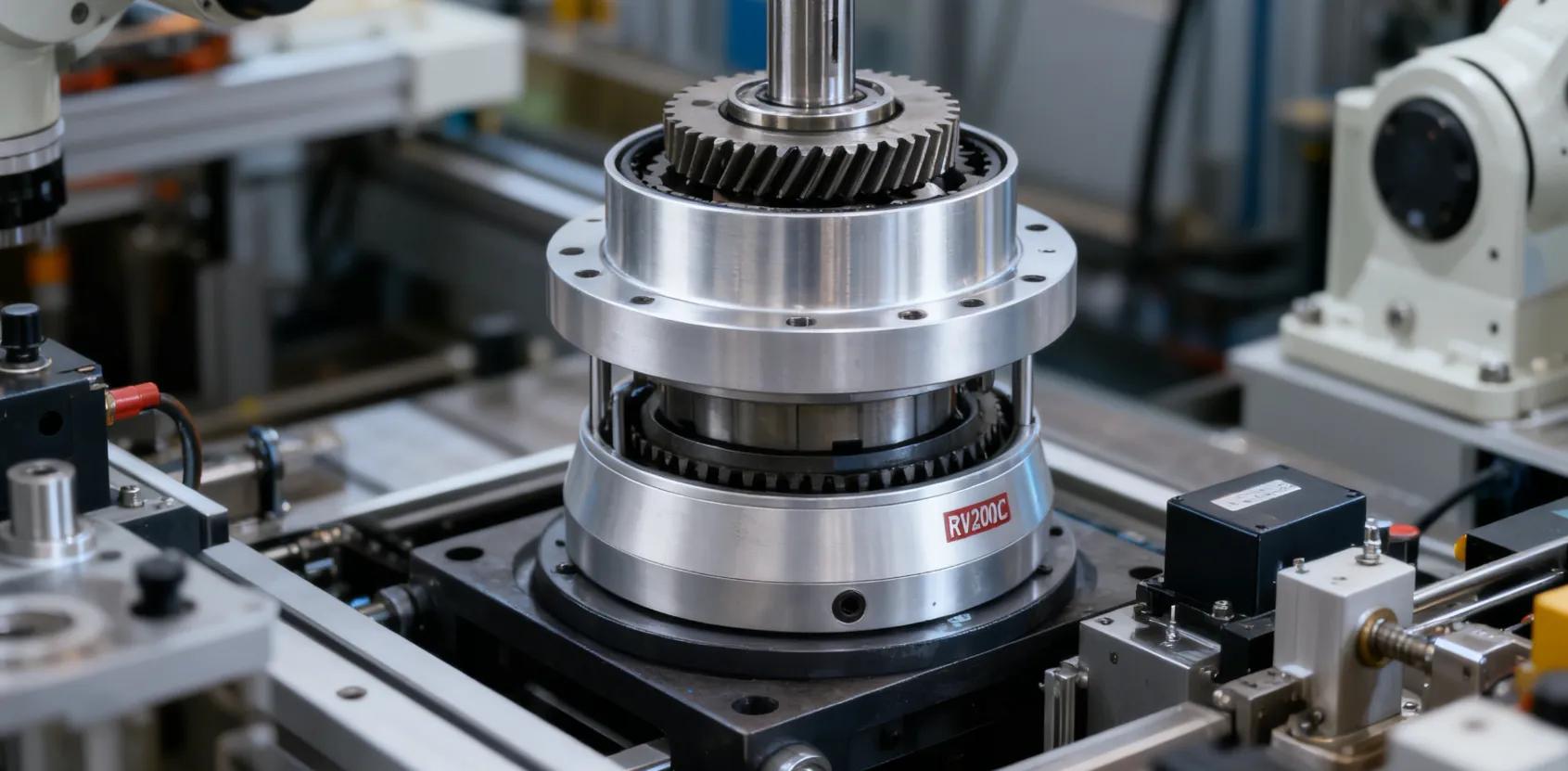

The RV200C RV-C Robot Reducer is a high-precision cycloidal gearbox specifically designed for advanced robotic and automation applications. It serves as a critical component in transmitting torque and reducing speed while maintaining exceptional accuracy and efficiency. This gearbox employs a two-stage reduction mechanism, combining spur gear and epicyclic gear reductions, to achieve smooth operation and high load capacity. Its hollow shaft configuration allows for the passage of cables, shafts, or other utilities, making it particularly suitable for compact robotic joints where space is at a premium. Engineered for demanding environments, the RV200C addresses real-world challenges such as vibration reduction, energy efficiency, and long-term reliability in industrial settings.

In practice, this gearbox solves issues like positional inaccuracies in robotic arms by providing consistent repeatability, which is vital for tasks in manufacturing assembly lines or medical diagnostics. Its design minimizes inertia and rotational vibration, enabling faster cycle times without sacrificing control. Professionals in automation can integrate it seamlessly with servo motors, thanks to its easy installation features, reducing downtime during setup or maintenance. The RV200C’s high efficiency rating helps lower operational costs by optimizing power usage, a key concern in energy-intensive operations. Furthermore, its robust construction withstands shock loads up to five times the rated torque, preventing failures in high-impact scenarios like material handling. By incorporating integrated angular ball bearings, it supports external loads effectively, eliminating the need for additional support structures and simplifying system design. This not only cuts costs but also enhances overall system compactness. For engineers facing integration hurdles, the gearbox’s modular nature allows for customization, ensuring compatibility with various robotic platforms. In summary, the RV200C stands out as a solution-oriented component that boosts productivity and precision in modern automation, backed by proven performance in diverse industries.

“The RV200C’s cycloidal design revolutionizes torque transmission, offering unparalleled precision for robotic applications.”

Key Features

Super Flat Design and Compact Structure

The super flat design of the RV200C minimizes its physical footprint, enabling integration into tight spaces without performance trade-offs. This feature solves spatial constraints in robotic systems, allowing for more flexible layouts in factories or labs.

High Precision and Low Backlash

With backlash less than 1 arc.min, the gearbox ensures exact positioning, addressing accuracy issues in precision tasks like welding or inspection, where even minor deviations can lead to defects.

High Rigidity and Efficiency

Its high rigidity supports heavy loads, reducing deformation, while efficiency above 75% minimizes energy waste, providing cost savings in continuous operations.

These features collectively enhance the RV200C’s utility in solving operational inefficiencies. The compact structure facilitates easier assembly, cutting installation time by up to 30%. High precision mitigates errors in automated processes, improving yield rates. Rigidity ensures stability under stress, extending equipment life. Efficiency translates to lower power bills and greener operations. Easy motor installation streamlines maintenance, reducing labor costs. In scenarios like AGV navigation, these attributes prevent downtime from mechanical failures. Engineers can rely on the gearbox for consistent performance, even in variable temperature environments. Overall, the RV200C’s features provide a comprehensive solution for enhancing robotic reliability and productivity.

Feature Summary

- Ultra-flat for space efficiency.

- Minimal backlash for accuracy.

- High efficiency for cost savings.

Product Construction and Components

The RV200C gearbox comprises essential components that work synergistically to deliver high performance. Key parts include the output flange for secure mounting, support flange for structural stability, pin gear housing that encases the pinning mechanism, cycloidal gears for eccentric motion, crankshaft for driving the gears, planetary gears for initial reduction, pin gear for load distribution, input gear for power intake, main bearing for smooth rotation, tapered roller bearings for handling axial loads, needle roller bearings with cage for reduced friction, and oil seals for lubrication retention.

- Output Flange: Provides a stable interface for output connection, ensuring torque transfer without slippage.

- Support Flange: Reinforces the structure, absorbing external forces to maintain alignment.

- Pin Gear Housing: Houses the pins, protecting the internal mechanism from contaminants.

- Cycloidal Gears: Enable eccentric motion, distributing loads across multiple teeth for high torque capacity.

- Crankshaft: Drives the cycloidal gears, converting input rotation into reduced output speed.

- Planetary Gears: Perform first-stage reduction, lowering speed while increasing torque.

- Pin Gear: Engages with cycloidal teeth, minimizing backlash through multi-point contact.

- Input Gear: Receives power from the motor, initiating the reduction process.

- Main Bearing: Supports the shaft, allowing smooth, low-friction rotation under load.

- Tapered Roller Bearings: Handle combined radial and axial loads, enhancing durability.

- Needle Roller Bearings with Cage: Reduce friction in high-speed areas, improving efficiency.

- Oil Seals: Prevent lubricant leakage, maintaining internal conditions for longevity.

In contexts like power take-off (PTO) shaft applications, where gearboxes interface with drive shafts, the RV200C’s hollow design complements PTO systems by allowing direct shaft passage, simplifying agricultural or industrial machinery setups. This compatibility addresses challenges in torque transmission over extended distances. Our company’s components are of superior quality, fully compatible with original equipment, and offered at competitive prices, ensuring value without compromising performance.

This construction solves problems like component wear by using rolling contact elements, which extend service life. In robotic arms, the crankshaft and cycloidal gears reduce vibration, improving control. The bearings ensure minimal energy loss, addressing efficiency concerns. Overall, the design provides a robust solution for high-precision needs, with our high-quality parts offering reliable, cost-effective alternatives.

Applications in Various Industries

Robotic Arms and Machine Tools

In robotic arms, the RV200C ensures precise movements for welding and assembly, solving accuracy issues in manufacturing.

Medical Equipment and Printing Machines

For medical devices, it provides smooth operation in surgical robots, addressing safety and precision requirements.

Automated Guided Vehicles (AGVs)

In AGVs, it enables accurate navigation, reducing errors in logistics.

These applications demonstrate the RV200C’s versatility in resolving industry-specific challenges. In machine tools, its rigidity supports high-load operations like milling, preventing deformation. Medical equipment benefits from low backlash for exact diagnostics. Printing machines achieve consistent quality through efficient torque control. AGVs gain from the gearbox’s durability in continuous use, minimizing maintenance. Additional uses include packaging machinery, where compact design fits tight spaces, and aerospace for vibration-resistant components. By integrating the RV200C, industries can enhance throughput, reduce waste, and improve safety, leading to measurable ROI.

Australian Product Policies and Compliance

In Australia, the RV200C gearbox complies with stringent product policies, including those under the Australian Consumer Law (ACL) for safety and quality. It meets standards from Safe Work Australia for machinery safety, ensuring hazard mitigation in industrial use. Import regulations via the Department of Home Affairs require conformity with electrical and mechanical safety certifications, such as AS/NZS standards for electromagnetic compatibility and vibration resistance.

Environmental policies under the Product Stewardship Act encourage sustainable manufacturing, with the RV200C’s efficient design reducing energy consumption. Compliance with the Work Health and Safety (WHS) regulations addresses noise and vibration risks, protecting workers. For robotic applications, adherence to ISO 10218 for robot safety is crucial. These policies solve issues like non-compliant imports by mandating testing and labeling. Businesses must ensure proper documentation for customs clearance, avoiding delays. The gearbox’s design aligns with Australia’s focus on innovation in automation, supported by grants from the Department of Industry, Science, Energy and Resources. In practice, this compliance facilitates seamless adoption in local industries, enhancing safety and efficiency while meeting legal requirements.

Australian policies emphasize safety and sustainability, making compliant products like the RV200C essential for market entry.

Further, the Therapeutic Goods Administration (TGA) oversees medical applications, requiring evidence of precision for devices. Environmental Protection Authority (EPA) guidelines ensure low emissions during operation. By adhering to these, the RV200C addresses regulatory challenges, providing peace of mind for Australian users.

Advantages of Choosing Our Company

Our company, located in Charlton Industrial Area, Australia, specializes in high-precision cycloidal gearboxes like the RV200C, offering innovative solutions tailored to automation needs. With a commitment to quality, we provide products that exceed industry standards, backed by exceptional customer support. Our advantages include cutting-edge designs that enhance efficiency, customizable options to fit specific applications, and competitive pricing that delivers value. We collaborate closely with clients to understand requirements, ensuring optimal performance and productivity gains.

Choosing us means accessing reliable, compatible components at affordable rates, solving common issues like high costs or incompatibility. Our Australian base ensures quick delivery and compliance with local regulations, reducing import hassles. Contact us at [email protected] for inquiries.

Our expertise in gearboxes extends to integrating with PTO shafts for versatile applications, ensuring seamless power transfer. With a focus on durability, our products minimize downtime, offering long-term savings.

FAQ

What is the rated torque of the RV200C gearbox?

The rated torque is 1,961 Nm, suitable for high-load robotic applications; ensure it matches your system’s requirements for optimal performance.

How does the hollow shaft design benefit integration?

It allows cables or shafts to pass through, simplifying wiring in compact robots and reducing overall system complexity.

What is the backlash specification?

Less than 1 arc.min, providing high precision for tasks needing accurate positioning like assembly or inspection.

Can the RV200C handle shock loads?

Yes, up to 9,800 Nm momentary torque, making it resilient in dynamic environments with sudden stops or starts.

What maintenance is required?

Regular lubrication checks and inspections every 2,000 hours; use specified grease to maintain efficiency and longevity.

Is it compatible with PTO shafts?

Yes, the hollow design supports PTO integration for agricultural or industrial machinery, ensuring efficient power transfer.

What are the operating temperature limits?

-10°C to 40°C ambient; consult for extreme conditions to avoid performance degradation.

How does it comply with Australian standards?

Meets AS/NZS safety and EMC requirements, ensuring legal and safe use in local industries.

What is the service life?

6,000 hours at rated conditions; proper installation extends this significantly.

Can ratios be customized?

Yes, options from 34.86 to 213; specify needs for tailored solutions to match motor speeds.

Customer Reviews

“I’ve been using the RV200C in our robotic assembly line for about six months now. It’s held up really well under constant use, with no noticeable wear. The precision is spot on, making our operations smoother than before. Definitely worth the investment.”

– Alex T., Manufacturing Engineer, Sydney

“This gearbox integrated seamlessly with our AGV system. The hollow shaft design made cabling a breeze, and it’s been reliable even in dusty warehouse environments. Saved us a lot of hassle during setup.”

– Jordan L., Logistics Manager, Melbourne

“Switched to the RV200C for our medical robot prototype, and the low backlash has improved accuracy tremendously. It’s compact yet powerful, fitting perfectly in our limited space. No complaints so far.”

– Sam K., Biomedical Technician, Brisbane

“Using it in a custom machine tool setup, and the high rigidity handles heavy loads without issue. Efficiency is better than our old gear, reducing energy costs a bit. Solid choice for precision work.”

– Riley M., Machinist, Perth

“The RV200C works great in our printing machine. Installation was straightforward, and it’s kept up with high-speed demands. Minimal maintenance needed, which is a plus for our busy schedule.”

– Taylor P., Production Supervisor, Adelaide