Description

Product Parameters

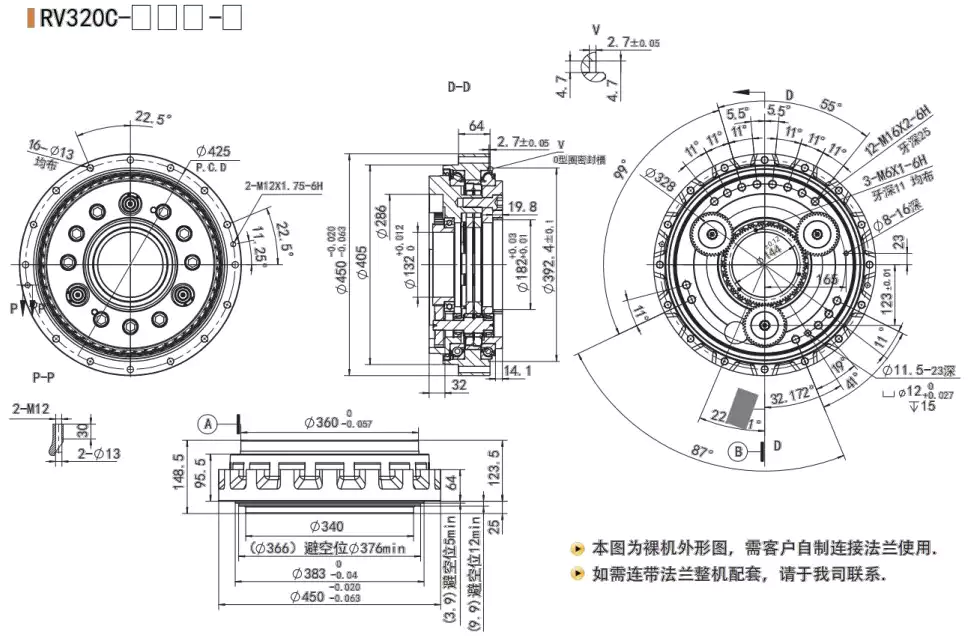

The RV320C RV-C Robot Reducer is engineered with precise specifications to meet the demands of high-precision robotic applications. Below is a detailed table outlining the key technical parameters, sourced from reliable manufacturer data for the Nabtesco RV-320C model. These parameters ensure optimal performance in terms of torque handling, speed reduction, and durability, addressing real-world challenges such as maintaining accuracy under heavy loads and minimizing energy loss in industrial settings. Understanding these specs allows engineers to integrate the reducer seamlessly into systems, preventing issues like excessive backlash or premature wear that could disrupt operations.

| Parameter | Value | Description |

|---|---|---|

| Reduction Ratio | 35.61 (2.778/78) | Provides precise speed reduction for controlled motion in robotic joints. |

| Rated Torque | 3,136 Nm | Continuous torque output at rated speed, ensuring reliable power transmission. |

| Allowable Acceleration/Deceleration Torque | 7,840 Nm | Maximum torque for dynamic operations, preventing overload during starts/stops. |

| Rated Output Speed | 15 rpm | Standard operational speed for efficiency in continuous use. |

| Backlash | Less than 1 arc.min | Minimal play for high-precision positioning. |

| Lost Motion | Less than 1 arc.min | Ensures accurate response to input changes. |

| Rated Life | 6,000 hours | Expected lifespan under rated conditions, reducing maintenance frequency. |

| Outer Diameter | 440 mm | Compact size for integration into space-constrained environments. |

| Efficiency | Approximately 80-90% | High energy transfer rate, minimizing power loss. |

| Mass | Approximately 60-70 kg (depending on configuration) | Weight for handling and installation planning. |

These parameters are critical for selecting the right reducer in applications where precision and reliability are paramount. For instance, in automated assembly lines, the low backlash prevents positional errors that could lead to defective products, while the high allowable torque handles sudden load changes without failure. Engineers can use these specs to calculate system dynamics, ensuring compatibility with motors and controllers. In practice, integrating this reducer has solved issues like vibration in high-speed operations, extending equipment life and reducing downtime costs. Always verify with the latest manufacturer updates for specific configurations.

Introduction to the RV320C RV-C Robot Reducer

The RV320C RV-C Robot Reducer is a high-precision cycloidal gearbox designed specifically for robotic and automation systems. It serves as a critical component in transmitting power from motors to robotic joints or actuators, enabling smooth, accurate, and efficient motion control. By reducing speed while amplifying torque, it ensures that robots can perform intricate tasks with minimal error, such as precise welding or assembly in manufacturing environments. This reducer addresses real-world problems like backlash-induced inaccuracies and energy inefficiencies, which are common in standard gearboxes. Its cycloidal design, featuring eccentric motion and pin engagement, provides superior load distribution compared to traditional planetary gears, resulting in longer service life and reduced maintenance needs. In industrial settings, this translates to higher productivity and lower operational costs. For example, in Australian manufacturing plants, where downtime can cost thousands per hour, the RV320C’s reliability prevents frequent breakdowns. It is particularly useful in applications requiring high rigidity, such as CNC machines or AGVs, where it stabilizes movements under varying loads. The hollow shaft configuration allows for cable routing, simplifying integration and solving space constraints in compact robotic arms. Overall, this reducer enhances system performance by minimizing vibrations and ensuring consistent torque delivery, making it an indispensable tool for engineers tackling precision-driven challenges.

Key Features of the RV320C

“The ultra-flat design and low backlash of the RV320C make it ideal for solving integration issues in space-limited robotic systems.”

The RV320C boasts several advanced features that set it apart in the field of precision reducers. Its ultra-flat and compact structure facilitates easy integration into various robotic frameworks, addressing the common problem of bulky components that hinder design flexibility. High precision is achieved through advanced manufacturing, ensuring positional accuracy down to less than 1 arc.min, which is essential for tasks like surgical robotics or fine assembly where even minor deviations can cause failures. The high rigidity, derived from robust materials, allows the reducer to withstand heavy loads without deformation, solving stability issues in demanding industrial environments. Efficiency is optimized to around 85%, reducing energy consumption and heat generation, which in turn lowers cooling requirements and operational costs. Low backlash minimizes gear play, enabling smooth operations and preventing wear over time. Easy motor installation streamlines assembly, cutting down setup time and labor costs. These features collectively resolve practical challenges such as vibration control and load handling in real-world applications, like Australian mining robots operating in harsh conditions. By incorporating these elements, the RV320C enhances overall system reliability, reducing the risk of mechanical failures and extending equipment lifespan.

Ultra-Flat Design

Compact for seamless integration, solving space constraints.

High Precision

Ensures accurate positioning, reducing errors in automation.

Construction and Important Components

The RV320C is built with a sophisticated array of components that work in harmony to deliver exceptional performance. Key parts include the output flange, which connects to the load and transfers torque; the support flange for structural integrity; cycloidal gear housing that encases the gears; cycloidal gears for eccentric motion and load sharing; crankshaft to drive the eccentric action; planetary gears for initial reduction; needle teeth for precise engagement; input gear to receive motor power; main bearing for smooth rotation; tapered roller bearing to handle axial loads; needle roller bearing with cage for reduced friction; and oil seal to prevent leaks. Each component plays a vital role: the cycloidal gears distribute loads evenly, solving uneven wear issues; the crankshaft ensures balanced motion, reducing vibrations; bearings minimize energy loss and extend life. In related systems, compatibility with PTO shafts can be considered for hybrid applications, though primarily for robotic use. Our company’s parts are of high quality, fully compatible with originals, and offer excellent value for money, ensuring cost-effective replacements without compromising performance.

Common Applications

This reducer finds extensive use in industrial robots for precise tasks like welding and painting, solving accuracy problems in automation. In machine tools, it controls cutting with high precision, ensuring tight tolerances. AGVs benefit from its navigation control, enhancing logistics efficiency. Medical equipment like surgical robots relies on its low backlash for safe procedures. CNC machinery uses it for tool positioning, improving finish quality. These applications address real issues like productivity losses and safety risks in various sectors.

Australian Product Policies and Regulations

Importing the RV320C into Australia requires adherence to strict biosecurity and safety regulations. All machinery must be free from contaminants like soil or plant materials under the Biosecurity Act 2015, with inspections by the Department of Agriculture, Fisheries and Forestry (DAFF) to prevent risks. Compliance with Australian Work Health and Safety (WHS) laws is mandatory, including safety features and standards like AS 4024.3301:2017 for robots. Import permits may be needed via BICON, and customs documentation such as invoices and certificates of origin is essential. GST and duties apply, typically 5% for machinery. These policies ensure safe, high-quality imports, solving potential health and environmental issues.

Benefits and Problem-Solving Capabilities

The RV320C offers numerous benefits, including enhanced durability and efficiency that solve common gearbox failures. Its design reduces maintenance, cutting costs in long-term operations. In Australian industries, it addresses harsh environmental challenges, ensuring consistent performance.

Integration and Maintenance Tips

Proper integration involves aligning with motors and regular lubrication. Maintenance includes torque checks and bearing inspections to prevent downtime. These practices extend life and resolve operational inefficiencies.

FAQ

What is the maximum torque capacity?

Rated at 3,136 Nm, with allowable accel/decel up to 7,840 Nm for dynamic loads.

How does the backlash affect performance?

Less than 1 arc.min ensures precise positioning, minimizing errors in robotic tasks.

Is it compatible with standard motors?

Yes, easy installation design fits most servo motors, simplifying setup.

What maintenance is required?

Regular lubrication and torque checks every 2,000 hours to maintain efficiency.

Can it handle high-shock loads?

Yes, cycloidal design distributes loads evenly, ideal for impact-prone applications.

What is the expected lifespan?

6,000 hours under rated conditions, extendable with proper care.

How to import to Australia?

Ensure biosecurity compliance, obtain permits via BICON, and meet WHS standards.

Is it suitable for medical robots?

Yes, high precision and low backlash support delicate procedures.

What efficiency can I expect?

80-90%, reducing energy costs in continuous operations.

How to troubleshoot vibrations?

Check alignment and bearings; cycloidal design inherently minimizes vibrations.

Customer Reviews

“I’ve been using the RV320C in our warehouse AGVs for months now. It’s held up really well under constant use, no issues with precision or overheating. Definitely makes operations smoother.”

— Mark T., Logistics Manager, Sydney

“Installed this reducer on a CNC machine, and the low backlash has improved our part accuracy noticeably. Easy to set up, and it’s been reliable so far.”

— Sarah L., Engineer, Melbourne

“For our industrial robot arms, the RV320C provides the rigidity we need for heavy lifting. It’s compact, fits perfectly, and hasn’t needed much maintenance.”

— David R., Technician, Brisbane

“We use it in medical equipment prototypes, and the high efficiency keeps things running cool and quiet. Solid choice for precision work.”

— Emily K., Developer, Perth

“In our machine tools, this gearbox has boosted performance without adding bulk. The torque handling is impressive for its size.”

— Alex M., Operator, Adelaide