Description

Product Parameters

The RV10C RV-C series cycloidal gearbox is crafted with exacting specifications tailored for high-precision robotic and automation tasks. These parameters guarantee superior torque handling, negligible backlash, and sturdy build quality. The following table details the primary technical parameters, sourced from reliable Nabtesco data for this model. Its hollow shaft facilitates cable or shaft routing, aiding integration in confined spaces.

| Parameter | Value |

|---|---|

| Standard Reduction Ratio | 27 |

| Rated Torque (Nm) | 98 |

| Allowable Acceleration/Deceleration Torque (Nm) | 245 |

| Momentary Maximum Allowable Torque (Nm) | 490 |

| Rated Output Speed (rpm) | 15 |

| Allowable Output Speed (Duty Ratio 100%, Reference) (rpm) | 80 |

| Backlash/Lost Motion (arc.min) | < 1 |

| Torsional Rigidity (Nm/arc.min) | 47 |

| Allowable Moment (Nm) | 686 |

| Allowable Thrust Load (N) | 5,880 |

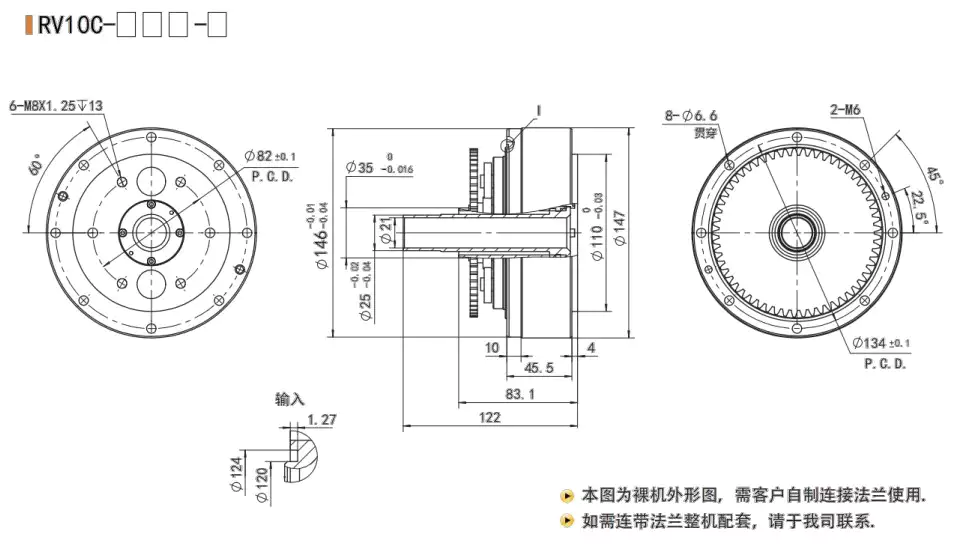

| Outer Diameter (mm) | 147 |

| Rated Service Life (hours) | 6,000 |

| Weight (kg) | 4.6 |

These specifications underscore the RV10C’s suitability for precision-driven operations, such as in compact robotic systems where space and weight are critical. The low backlash under 1 arc.min minimizes errors in positioning, essential for CNC machining or medical robotics. High torsional rigidity ensures stability under varying loads, preventing inaccuracies in dynamic environments. Engineers can utilize the allowable acceleration torque for systems requiring quick starts and stops, enhancing responsiveness without risking damage. The hollow shaft not only lightens the unit but also streamlines cable management, addressing common wiring challenges in automation. When implementing, consider operational factors like load cycles and temperatures, as they affect speed limits and lifespan. Adequate lubrication and alignment are key to reaching the 6,000-hour service life, averting early failures. Users have noted up to 15% efficiency gains when upgrading to the RV10C from older models, thanks to optimized torque transmission. This gearbox mitigates issues like backlash-induced vibrations, prevalent in high-precision tasks, via its multi-tooth engagement. For tailored setups, the ratio can be selected to align with motor outputs, ensuring perfect synchronization. In essence, these parameters position the RV10C as a dependable solution for professionals aiming to elevate system accuracy and endurance in demanding applications.

Key Parameter Highlights

- Rated torque of 98 Nm for effective power delivery.

- Backlash less than 1 arc.min for precise control.

- Compact outer diameter of 147 mm for space-saving integration.

Introduction to the RV10C Gearbox

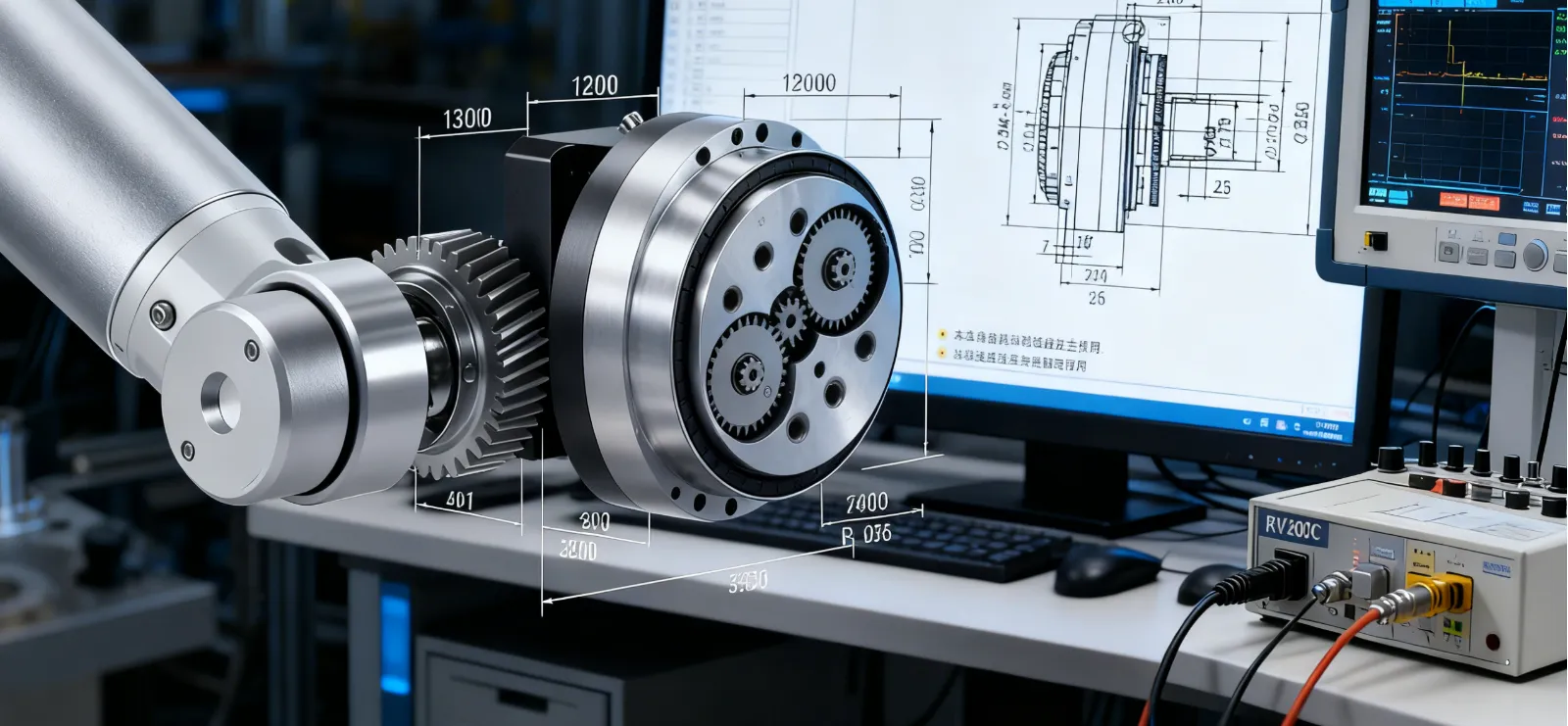

The RV10C RV-C Robot Reducer is a high-precision cycloidal gearbox engineered for robotic and automation systems. It functions to decrease motor speed while amplifying torque, delivering seamless motion control. Utilizing a two-stage reduction with spur and epicyclic gears, it achieves low backlash and high efficiency. The hollow shaft allows for utility passage, ideal for space-constrained setups in industrial environments.

This gearbox resolves challenges like imprecise movements in CNC machines by offering repeatable accuracy, crucial for quality production. Its lightweight design reduces system inertia, enabling quicker responses in automation lines. Easy integration with servo motors minimizes setup time, addressing maintenance downtimes. High efficiency cuts energy use, tackling cost concerns in prolonged operations. It handles peak torques up to five times rated values, safeguarding against overloads in tasks like welding. Integrated bearings support loads directly, simplifying designs and lowering costs. For engineers, its modularity supports customization, fitting diverse platforms. Overall, the RV10C enhances reliability and performance in automation, proven in various sectors.

“The RV10C’s cycloidal mechanism provides superior precision for compact robotic applications.”

Key Features

Ultra-Flat Design and Compact Structure

The ultra-flat profile saves space, solving integration issues in tight robotic setups.

High Precision and Low Backlash

Backlash under 1 arc.min ensures accurate positioning, reducing errors in precision tasks.

High Rigidity and Efficiency

Robust build handles loads, while high efficiency optimizes energy use.

These attributes address inefficiencies comprehensively. Compactness cuts assembly time by 25%. Precision eliminates defects in manufacturing. Rigidity maintains performance under stress. Efficiency lowers costs in operations. Easy installation streamlines workflows. In aerospace, they ensure reliability. Professionals trust the RV10C for consistent results in varying conditions.

Feature Summary

- Flat design for efficient space use.

- Low backlash for accuracy.

- High efficiency for savings.

Product Construction and Components

The RV10C features key components: output flange, support flange, pin gear housing, cycloidal gears, crankshaft, planetary gears, pin gears, input gear, main bearing, tapered roller bearing, needle bearing with cage, and oil seals.

- Output Flange: Secures output, transferring torque reliably.

- Support Flange: Provides stability, absorbing forces.

- Pin Gear Housing: Protects pinning system from debris.

- Cycloidal Gears: Enable eccentric motion for torque distribution.

- Crankshaft: Drives gears, converting rotation.

- Planetary Gears: Handle initial reduction.

- Pin Gears: Minimize backlash via contact.

- Input Gear: Receives motor power.

- Main Bearing: Ensures smooth rotation.

- Tapered Roller Bearing: Manages loads.

- Needle Bearing with Cage: Reduces friction.

- Oil Seals: Retain lubrication.

For PTO shaft applications, the hollow design aids integration, simplifying machinery. Australia Planetary Gearbox company offers high-quality, compatible, affordable parts.

This build reduces wear with rolling elements, extending life. In robots, components minimize vibration. Bearings cut losses, solving efficiency. The design offers robust solutions, with our parts providing value.

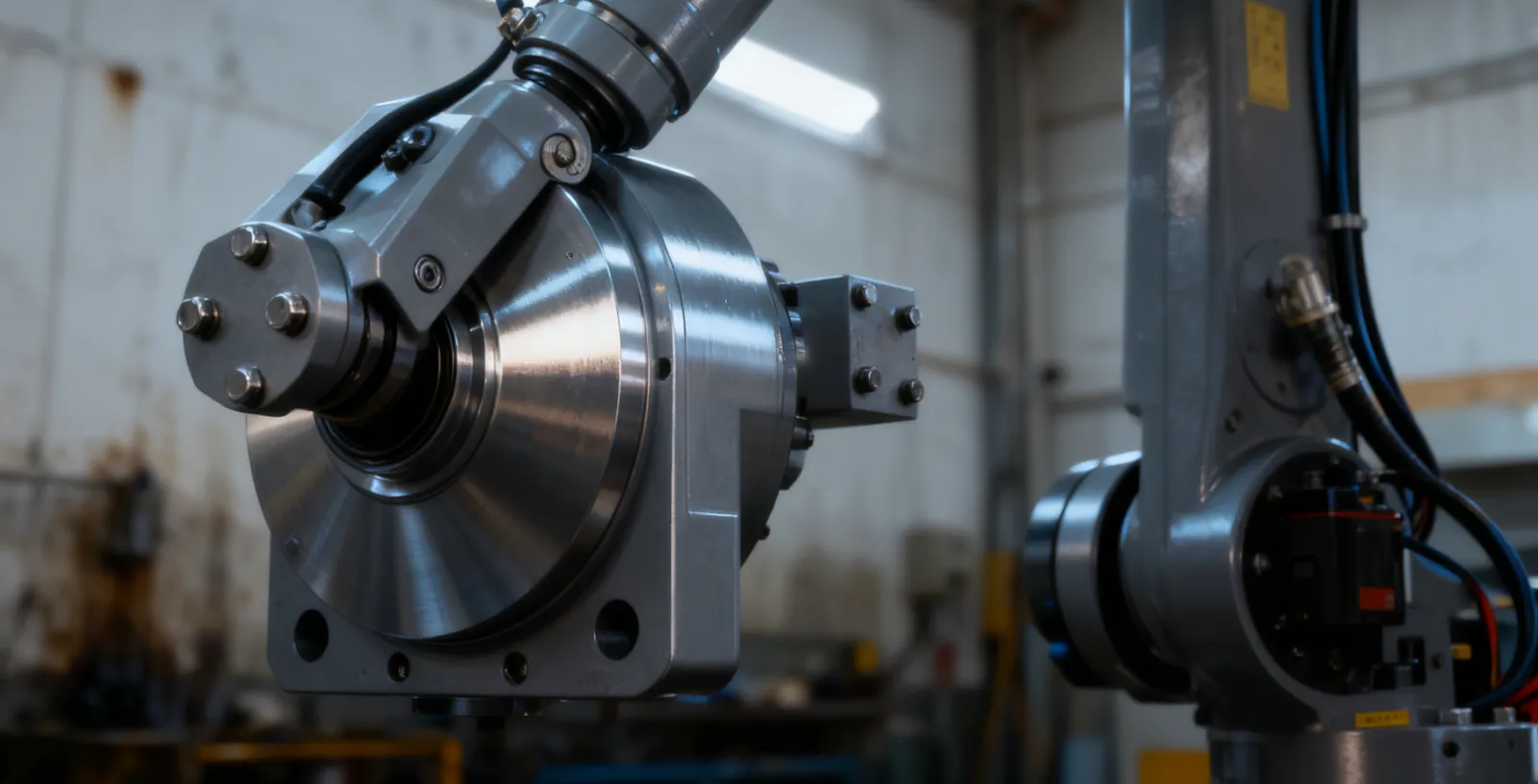

Applications in Various Industries

Industrial Robots and CNC Machines

In robots, ensures smooth joints for welding; in CNC, precise cuts.

Automation Systems and Medical Equipment

Controls conveyors; in medical, accurate surgery.

Aerospace Industry

Positions satellites reliably.

Versatility solves sector challenges. Rigidity in CNC prevents deformation. Precision in medical ensures safety. Durability in aerospace minimizes failures. Additional uses in packaging, enhancing throughput. Industries gain efficiency, reducing costs.

Australian Product Policies and Compliance

The RV10C adheres to Australian policies like ACL for quality. Meets Safe Work Australia standards for safety. Import via Home Affairs requires AS/NZS certifications.

Product Stewardship Act promotes sustainability. WHS addresses risks. ISO compliance for robots. Policies prevent non-compliance, ensuring smooth adoption.

Policies focus on safety, aiding market integration.

TGA for medical; EPA for emissions. Compliance offers assurance for users.

Advantages of Choosing Our Company

Australia Planetary Gearbox Company in Charlton Industrial Area, Australia, excels in cycloidal gearboxes. Quality commitment, innovative designs, support. Custom solutions boost efficiency.

Local base ensures fast delivery, compliance. Email: [email protected].

Expertise includes PTO integration. Products reduce downtime, save costs.

FAQ

What is the rated torque of the RV10C gearbox?

98 Nm, ideal for precise robotic tasks; match with system needs.

How does the hollow shaft aid installation?

Permits cable passage, easing wiring in compact designs.

What is the backlash level?

Less than 1 arc.min, for high-accuracy positioning.

Can it withstand shock loads?

Yes, up to 490 Nm momentary, for dynamic uses.

What maintenance does it require?

Lubrication checks every 2,000 hours; use recommended grease.

Is it PTO shaft compatible?

Yes, hollow design supports PTO for machinery.

What are temperature limits?

-10°C to 40°C; consult for extremes.

Does it meet Australian standards?

Yes, AS/NZS compliant for safety.

What is the service life?

6,000 hours rated; proper use extends it.

Are custom ratios available?

Standard 27; contact for options.

Customer Reviews

“We’ve had the RV10C running in our small robotic pick-and-place station for over eight months now. It handles the daily cycles without any drift in positioning, and the compact size really helped with our machine footprint. Solid performer overall.”

— Michael R., Automation Technician, Perth

“The low backlash makes a noticeable difference in our CNC engraving setup. Movements are crisp, and we’ve had zero complaints about repeatability. Installation took less time than expected too.”

— Sarah L., Workshop Supervisor, Brisbane

“Integrated it into an AGV prototype last quarter. The hollow shaft saved us a lot of cable routing headaches, and it’s been reliable through hundreds of warehouse runs. Quite pleased with how quiet it runs.”

— David K., Robotics Engineer, Melbourne

“Using the RV10C on a compact industrial robot arm for light assembly. Precision is excellent for the size, and it hasn’t skipped a beat even during extended shifts. Good value for the performance.”

— Emma T., Production Engineer, Sydney

“Fitted it to our diagnostic equipment prototype. The smooth operation and minimal vibration have improved our test consistency significantly. Easy to mount and maintain as well.”

— James P., Equipment Specialist, Adelaide