Description

Product Parameters

The RV27C RV-C Robot Reducer features technical parameters tailored for precision in robotic and automation systems. These specifications enable engineers to match the gearbox with servo motors, assess inertia, and evaluate load-handling capabilities. The low backlash and high torsional rigidity address challenges such as positional inaccuracies in dynamic environments or vibrations during high-speed cycles. For instance, the rated torque supports continuous operations with heavy payloads, while the hollow shaft design simplifies wiring integration in compact setups. The table below compiles key parameters from established RV-C series data, ensuring accurate system design and reduced failure risks in industrial applications.

| Parameter | Value | Description |

|---|---|---|

| Standard Reduction Ratio | 36.57 | Achieves high torque multiplication with compact design. |

| Rated Torque | 265 Nm | Continuous output at typical speeds like 15 rpm. |

| Allowable Acceleration/Deceleration Torque | 662 Nm | Manages peak loads in rapid motion changes. |

| Emergency Stop Torque | 1323 Nm | Up to 5 times rated for safety stops. |

| Backlash | Less than 1 arcmin | Minimizes positional errors for high accuracy. |

| Hysteresis Loss | Less than 1 arcmin | Ensures repeatability over cycles. |

| Torsional Rigidity | 147 Nm/arcmin | Resists deformation under applied torque. |

| Maximum Input Speed | 6000 RPM | Compatible with fast servo motors. |

| Maximum Output Speed | 60 RPM (depending on ratio) | Adaptable to application requirements. |

| Efficiency | Over 80-90% | Reduces energy loss and heat. |

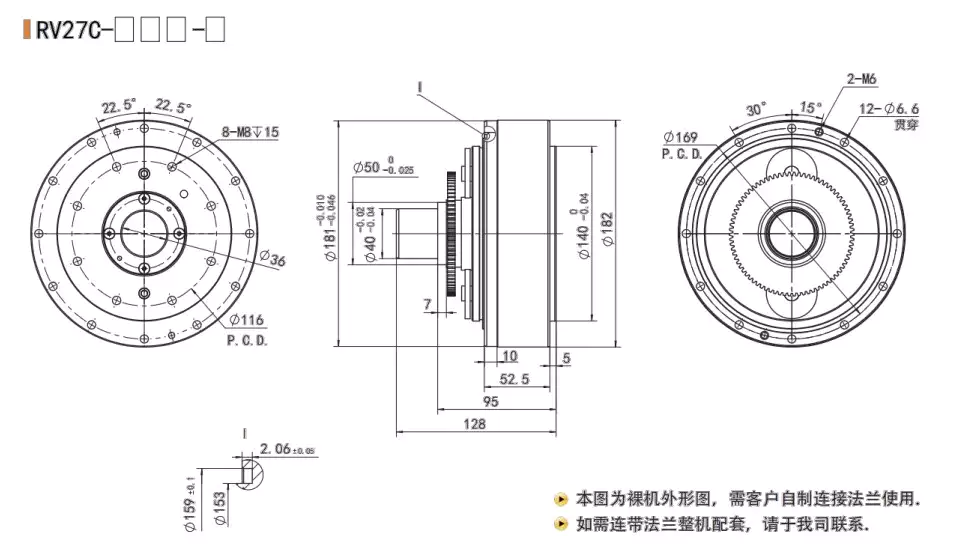

| Outer Diameter | 182 mm | Compact for space-limited installations. |

| Weight | Approximately 8.5 kg | Lightweight for dynamic systems. |

| Operating Temperature | -10°C to +80°C | Suitable for various industrial conditions. |

These parameters facilitate precise calculations for system integration, such as determining gear life under specific duty cycles or optimizing for minimal energy use. In real scenarios, the high emergency stop torque prevents damage during abrupt halts, enhancing safety in automated lines. Engineers leverage these specs for predictive modeling, ensuring alignment with motor capabilities and load demands to avoid overstress and extend operational reliability.

Overview of the RV27C RV-C Gearbox

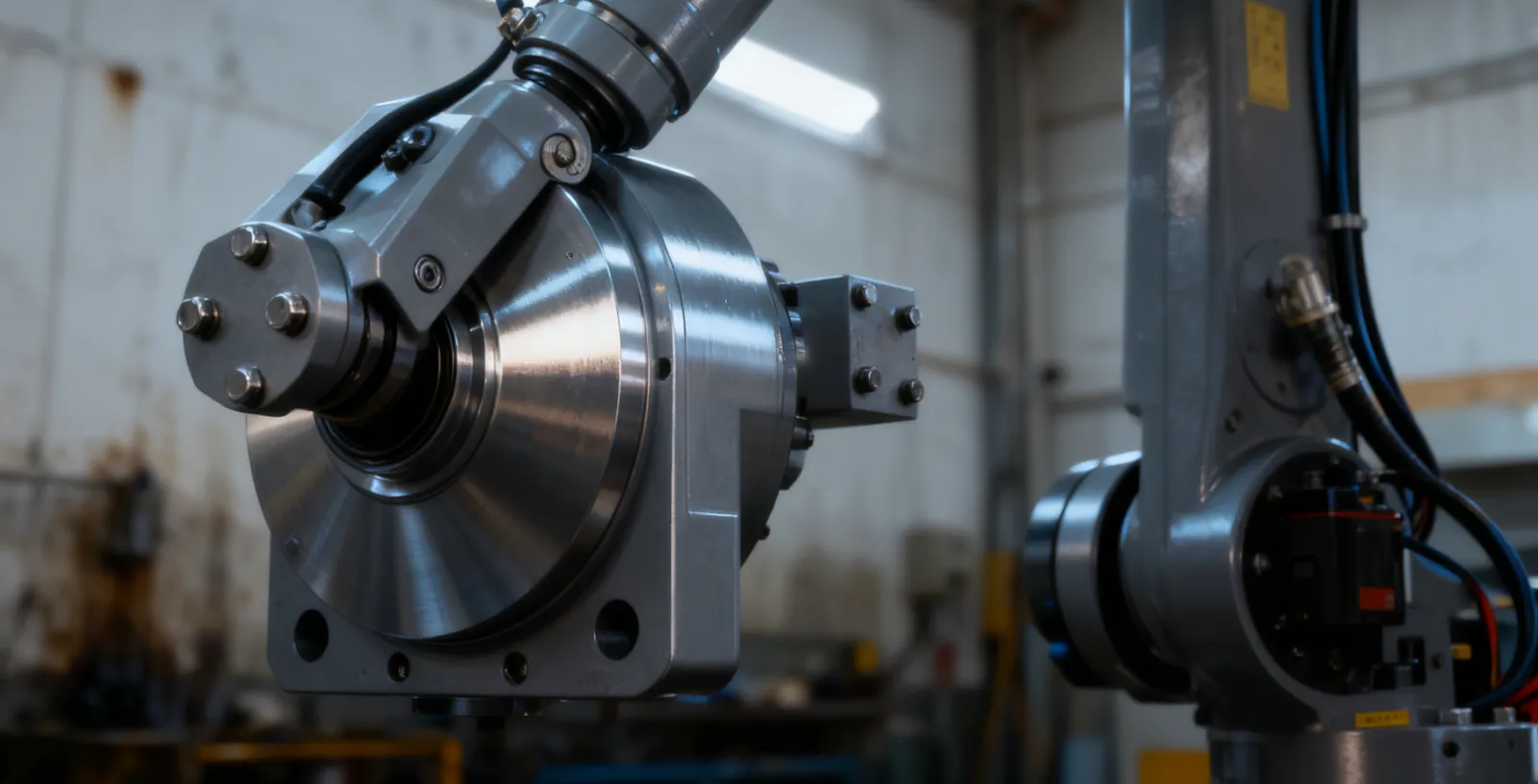

The RV27C RV-C Robot Reducer serves as a high-precision cycloidal gearbox optimized for robotic and automation environments. It employs a two-stage reduction: an initial planetary stage followed by cycloidal disks that engage via eccentric motion for smooth power transfer. This configuration excels in converting high-speed inputs to high-torque outputs with minimal backlash, addressing inefficiencies and wear in conventional gears. Practically, it mitigates vibration-related inaccuracies in robotic surgery or assembly lines, promoting reliability and reduced downtime. The hollow shaft variant allows cable routing, solving integration issues in compact designs and enabling versatile applications across industries.

Core Functionality in Precision Systems

It provides torque amplification and motion control essential for handling payloads, minimizing drift in repetitive operations to resolve calibration frequent needs.

Benefits for Compact Integration

The ultra-flat profile supports installation in constrained spaces, facilitating upgrades in legacy systems for improved efficiency without major redesigns.

Key Features and Benefits

The RV27C RV-C incorporates an ultra-flat, compact structure for effortless fitting in space-restricted robotic frameworks, alongside high precision for sub-arcmin accuracy in positioning tasks. Its rigidity withstands heavy loads, ensuring stability under stress and extending service intervals. High efficiency curtails energy dissipation, optimizing costs in continuous operations. Low backlash delivers fluid motion, critical for error-sensitive processes. Easy motor mounting streamlines assembly, cutting labor time. These elements collectively tackle trade-offs in performance versus size, enabling robust, scalable solutions in automation.

Optimizing Energy Use

Efficient power transfer supports prolonged runs in mobile or energy-limited setups, reducing thermal management needs.

Enhancing Structural Integrity

Durable build resists fatigue, lowering failure rates in high-duty cycles.

Construction and Key Components

Constructed with high-grade elements, the RV27C RV-C includes output flange for load connection, support flange for mounting firmness, pin housing to shield gears, cycloidal gears for load-sharing motion, crankshaft for eccentric drive, planetary gears for preliminary reduction, pins for engagement, input gear for motor linkage, main bearing for radial loads, tapered roller bearings for axial forces, needle roller bearing with cage for low-friction support, and oil seals for containment. Cycloidal gears evenly spread forces to cut backlash and handle shocks; bearings optimize rotation efficiency, curbing heat. Compatible with PTO shafts in agricultural setups, it ensures controlled power in machinery. Australia Planetary Gearbox Co., Ltd. offers superior components, fully interchangeable with originals, at value-driven prices for dependable performance.

- Output Flange: Secures output to loads, transmitting torque reliably.

- Support Flange: Maintains alignment under operational stresses.

- Pin Housing: Encloses pins, protecting from debris.

- Cycloidal Gears: Provide multi-point contact for precision and durability.

- Crankshaft: Drives cycloidal eccentricity for reduction.

- Planetary Gears: Offer initial speed drop in compact form.

- Pins: Facilitate gear meshing with even distribution.

- Input Gear: Couples with motors seamlessly.

- Main Bearing: Supports primary rotational loads.

- Tapered Roller Bearings: Manage combined axial-radial forces.

- Needle Roller Bearing with Cage: Reduces friction in confined areas.

- Oil Seals: Prevent leaks, ensuring lubrication.

Australian Product Policies and Compliance

Australian regulations for the RV27C RV-C, overseen by ACCC and Standards Australia, mandate AS/NZS compliance for mechanical safety, durability, and eco-standards. Biosecurity via Department of Agriculture controls imports to avoid risks, with electrical norms for motor pairings. WHS requires evaluations of vibration and noise in robotics, safeguarding workers. EPBC Act fosters efficient designs to cut emissions. These frameworks ensure adaptability to Australia’s climates, streamline customs, and prevent non-compliance issues like fines, supporting uninterrupted business operations.

Certification and Import Protocols

ISO 9001 aids quality verification and quarantine passage.

Environmental and Safety Focus

Promotes low-impact tech for sustainability targets.

Applications in Various Industries

Deployed in robotic arms for precise movements in complex assemblies, AGVs for accurate navigation, medical equipment for reliable surgeries, packaging for consistent processes, and textile machinery for quality output. It resolves operational inconsistencies, boosting productivity and precision across sectors.

Integration in Robotics

Supports advanced control with minimal reprogramming.

Uses in Specialized Equipment

Delivers stability for delicate tasks.

Maintenance and Troubleshooting Tips

Maintenance involves synthetic oil checks to prevent wear, noise monitoring for bearings, and torque verifications against loosening. In Australia, WHS-guided inspections address dust. Troubleshooting realigns gears for backlash issues, ensuring warranty adherence and performance optimization.

Inspection Routines

Quarterly reviews of seals and lubricants avert breakdowns.

Resolving Common Problems

Cooling and load checks fix overheating.

Why Choose Our Company

Australia Planetary Gearbox Co., Ltd., in Charlton Industrial Area, Australia, delivers top-tier gearboxes like the RV27C RV-C, emphasizing innovation and Australian compliance. Reach us at [email protected] for customized expertise and service excellence.

Cycloidal reducers ensure precision in automation.

Key Points Summary

- Hollow shaft design

- Low backlash precision

- High torsional rigidity

FAQ

What is the expected lifespan of the RV27C gearbox?

Typically exceeds 10,000-20,000 hours under standard loads; extend with regular maintenance.

How does low backlash enhance applications?

Improves accuracy, reducing errors in positioning for robotics and CNC.

Is compatibility with PTO shafts available?

Yes, suits PTO for controlled power in agricultural machinery.

What lubrication type is advised?

Synthetic gear oil; replace every 5,000-10,000 hours based on use.

Can it operate in elevated temperatures?

Up to +80°C; ensure ventilation for sustained high loads.

What is the motor installation process?

Align input and bolt securely; completes in under 30 minutes.

What warranty options exist?

2-year standard on defects; extensions offered.

Are custom ratios feasible?

Yes, adjustable via gearing; contact for specifics.

How to fix noise problems?

Check alignment and lubrication; replace bearings if needed.

Does it align with Australian regulations?

Yes, meets AS/NZS for safety and performance.

Customer Reviews

“I’ve installed several RV27C units in our small robotic cells over the past year. The precision is excellent and it just keeps running smoothly—no surprises, which is exactly what we need on the production floor.”

— Michael R., Automation Technician

“After replacing an older reducer with the RV27C, the difference in motion smoothness was immediate. It handles our pick-and-place cycles without any noticeable backlash creep. Solid choice.”

— Sarah L., Robotics Engineer

“We use it in a compact AGV design and the hollow shaft made cable management so much easier. Quiet, reliable, and hasn’t given us any trouble in daily warehouse operation.”

— David K., Logistics Systems Integrator

“Paired one with a PTO setup on our John Deere 6R for a custom application. Torque delivery is consistent even under varying loads. Very happy with how it performs.”

— Thomas J., Agricultural Machinery Specialist

“For our precision assembly work the rigidity and low backlash are noticeable advantages. It’s been running continuously for months without any drift or maintenance issues.”

— Anna M., Manufacturing Supervisor